Plastic Film-Laminated Steel Sheets

Polyester-based plastic film-laminated steel sheets

EXUMTM

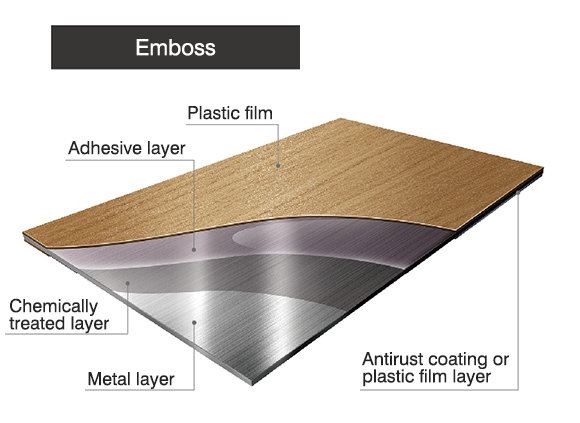

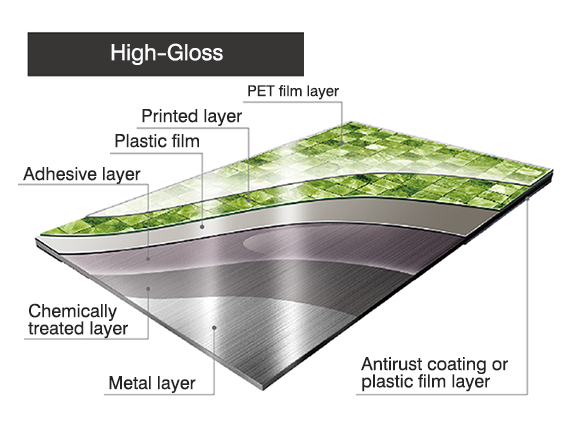

EXUM incorporates galvanized steel sheets, stainless steel sheets, and aluminum alloy sheets as a base material. EXUM is a polyester-based plastic film-laminated steel sheet manufactured by our multi-layer extrusion technology.

This material is primarily used in interior applications due to the combination of metal strength, workability, and design qualities.

Characteristics

- EXUM has a surface hardness higher than PVC film and polyolefin film.

Many options are available including solid colors, printed patterns, high-gloss options to satisfy various design requirements. - This material has excellent bending properties.

- EXUM can have a vivid appearance with the mirror finish.

Applications

EXUM is utilized in various interior applications due to its beautiful appearance and excellent workability.

- interior applications

: Unit baths, elevators, etc. - Low-current devices

: Refrigerators, etc. - Other

Unit baths

Unit baths Elevators

Elevators

Manufacturing Scope and Order Conditions

-

Lot

A lot of 2.5 tons or more is required to order a product having the same specifications such as the same sheet thickness, width, color and embossing.* Please order in lots of at least 2.5 tons as special request lots smaller than this will require an extra fee.

Performance

* Table can be scrolled horizontally

| Specific test | Test conditions | Criteria | EXUM | |

|---|---|---|---|---|

| Adhesion | Conformal Erichsen 6 mm extrusion |

25±5°C | No separation | Nothing abnormal |

| Bendability | Adhesion and bending test | 25±5°C, 0T | No cracking, breakage, and separation | Nothing abnormal |

| Processability at low temperature | 90° bend test | 0±1°C, R=2 | No cracking, breakage, and separation | Nothing abnormal |

| Resistance to boiling water | Dipping in boiling water | Submerged in water for 5 minutes after 60 minutes of immersion | No shrinkage, cracking, breakage, creasing, separation, and marked fading | Nothing abnormal |

| Chemical resistance | 5-minute immersion (20±2°C) |

10% hydrochloric acid | No rust, stain, and marked fading | Nothing abnormal |

| Saturated calcium hydroxide | ||||

| 10% sulfuric acid | ||||

| Aqueous solution of sodium hydroxide (100 g/L) | ||||

| Ethanol | ||||

| Kerosene | ||||

| Corrosion resistance | Complies with salt spray test JIS Z 2371 |

JIS K 6744 Type C: 1,000 hours |

No rust | Nothing abnormal |

| Self-extinguishability | Gas burner heating for 20 seconds | Extinguishes immediately | Extinguishes immediately within 10 seconds | |

*1 The data described above represents the specified values in our company and does not represent guaranteed values.

*2 Please contact us to inquire on the certification of fire-resistant materials.

Contact Us

Designed materials Department