Plastic Film-Laminated Steel Sheets

Plastic Film-Laminated Steel Sheets

HISHIMETALTM

HISHIMETAL is a composites material that is produced by laminating PVC film on a base material such as galvanized steel sheets, stainless steel sheets and aluminum sheets. PVC film is a general purpose film and we have employed it as a laminating film for many years.

This material is used in many different industries because it has metal strength and workability in addition to the design qualities and functional properties of plastic film.

Characteristics

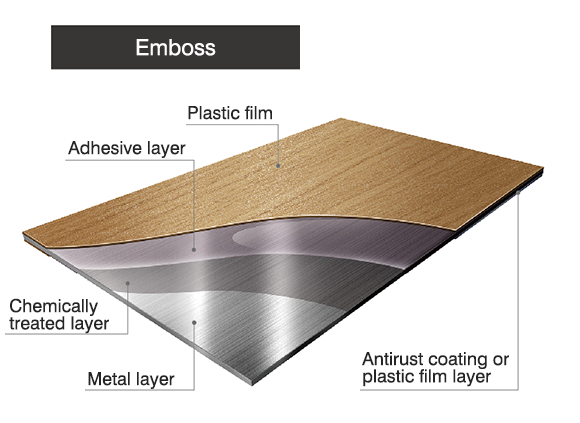

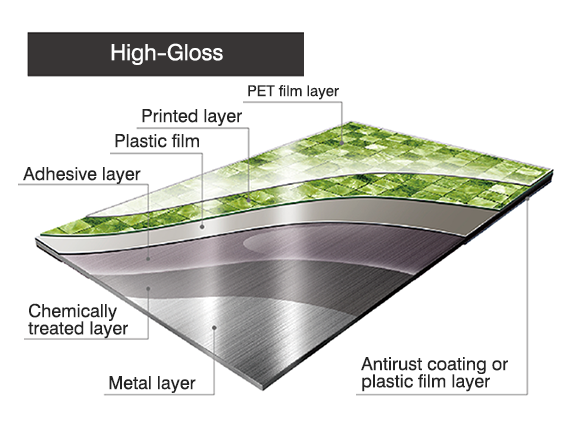

- HISHIMETAL is a laminated material including a metal layer and a PVC film layer available in many different color patterns and emboss.

Many options are available including solid colors, printed patterns, high-gloss options to satisfy various design requirements. - This material can be used in typical metal forming processes such as bending, cutting, and pressing.

- This material can be used for outdoor applications by laminating a weather-resistant PVC film.

Applications

HISHIMETAL is widely utilized in many different applications due to its excellent weatherbility, corrosion resistance and a variety of colors and patterns.

- Interior applications

Prefabricated baths, curtain rails, closet doors, spandrels, and others - Exterior applications

Residential building accessories, gutters, shutter cases, doors, factory roofs, walls, and others - Light electrical appliances

Refrigerators, audio equipment, medical equipment, measuring instruments, lighting, and others - Other

Automotive parts, bicycle mudguards, and others

Prefabricated baths

Prefabricated baths Residential outdoor applications

Residential outdoor applications Factory roofs

Factory roofs

Manufacturing Range and Order Conditions

-

Lot

A lot of 2.5 tons or more is required to order a product having the same specifications such as the same sheet thickness, width, color and emboss.* Please order in lots of at least 2.5 tons as special request lots smaller than this will require an extra fee.

Performance

* Table can be scrolled horizontally

| Specific test | Test conditions | Criteria | HISHIMETAL | |

|---|---|---|---|---|

| Adhesion | Conformal Erichsen 6 mm extrusion |

25±5°C | No separation | Nothing abnormal |

| Bendability | Adhesion and bending test | 25±5°C、0T | No cracking, breakage, and separation |

Nothing abnormal |

| Processability at low temperature | 90° bend test | 0±1°C,R=2 | No cracking, breakage, and separation |

Nothing abnormal |

| Resistance to boiling water | Dipping in boiling water | Submerged in water for 5 minutes after 60 minutes of immersion | No shrinkage, cracking, breakage, creasing,separation, and marked fading |

Nothing abnormal |

| Chemical resistance | 5-minute immersion (20±2°C) |

10% hydrochloric acid | No rust, stain, and marked fading | Nothing abnormal |

| Saturated calcium hydroxide | ||||

| 10% sulfuric acid | ||||

| Aqueous solution of sodium hydroxide (100 g/L) | ||||

| Ethanol | ||||

| Kerosene | ||||

| Corrosion resistance | Complies with salt spray test JIS Z 2371 |

JIS K 6744 Type A: 2,000 hours |

No rust | Nothing abnormal |

| JIS K 6744 Types B and C: 1,000 hours |

||||

| Weather resistance | Sunshine Weather-Ometer, complies with JIS A 1415 | JIS K 6744 Type A: 2,000 hours |

No rust, breakage, and marked fading | Nothing abnormal |

| JIS K 6744 Type B: 1,500 hours |

||||

| Self-extinguishability | Gas burner heating for 20 seconds | Extinguishes immediately | Nothing abnormal | |

* Please contact us to inquire on the certification of fire-resistant materials.

Contact Us

Designed materials Department